CONTROL VALVES AND PRESSURE

Mascot

GFlo – Globe Control Valve

-

Reliable High-thrust Cylinder Actuator.

-

Accurate Positioning.

-

High Repeatability.

-

Double Stem Guiding does not come in contact with operating fluid.

-

Sufficient Clearance between plug head and seat retainer to avoid galling.

-

Self-Aligning seat ring.

-

Shutoff assisted by fluid pressure, cylinder spring and air pressure.

-

Corrosion resistant construction.

-

High Thrust cylinder overcomes high pressures to provide exceptional tight shutoff.

-

Anti-Cavitation and Noise Attenuation trim options.

-

Heavy-Duty plug stem.

-

Excellent Interchangeability between sizes and other MASCOT products.

-

Valve design minimizes requirements for stocking spare parts.

Stiff, Heavy-Duty parts provide extended life.

DiskFlo – Butterfly Valve

-

Soft Seat: To help energize the soft seat to bubble-tight shutoff in either flow direction, including alternating flow applications, Jam-Lever Toggle seating concepts utilize the pressure drop across the valve. Jam-lever Toggle soft seats achieve ANSI Class VI shutoff.

-

Metal Seat: For applications involving temperatures higher than those permitted by the Jam-lever Toggle soft seat, metal seats are used. A highly flexible lip, which assures full circle contact between the seat and disc when the valve is closed, is incorporated in the design. The lip flexibility permits breakout torque for the metal seat is the same or less than soft seat breakout torque. ANSI class IV shutoff is achieved through DiskFlo metal seats.

-

Dual Seat: DiskFlo dual seats incorporate both the Jam-lever Toggle soft seat and the flexible lip metal seat for added protection in unclean fluids or demanding applications. It also makes the DiskFlo a Firesafe Butterfly Valve.

-

DiskFlo Double Eccentric Cammed Disc To lift it out of the seat immediately upon actuation, a double offset has been designed into the disc. This avoids wear on the seat and disc, reducing leakage and parts replacement. The throttling also improves as the friction is eliminated.

-

Flow Direction Jam-lever Toggle seating allows DiskFlo to flow either shaft downstream or shaft upstream, depending on service conditions. With the shaft downstream the flow tends to open the valve. With the shaft upstream the flow tends to close the valve.

-

Flow Characteristics The inherent flow characteristic of the DiskFlo valve is a modified parabolic. Other characteristic curves are achievable by means of a MASCOT HiFlo Positioner or a SMART positioner.

VFlo – Segmented (V-Notch) Ball Valve

The VFlo – Segmented Ball Valve is designed to provide effective control for demanding applications. It is a rugged design segmented ball valve which overcomes the problems of harsh, particle entrained processes, and fibrous/unclean services. The VFlo also provides accurate, reliable control in a broad range of applications, such as Chemical, Power and Oil & Gas, Petro-Chemical & Pulp & Paper.

The VFlo addresses and solves many long-standing challenges faced by traditional ball valves like:

-

Piping forces that unevenly load the seal

-

Low rangeability due to limited orifice characterization

-

Unsatisfactory shutoff capabilities

EFlo – Eccentric Plug Valve

-

Non-Crossover Shaft:

-

Pocket-less flow-path tolerates slurries, even up to 3% paper stock.

-

Unobstructed flow when fully open.

-

Up to 70% greater capacity than other ERP control valves.

-

Not eroded by process-born particles.

-

-

Eccentric Rotary Plug:

-

Plug does not rub seat ring. Less wear, less friction, more precision.

-

Flow direction assists movement to safety position on air-failure.

-

Tight Shut-off, Class IV (Metal Seat), Class VI (Soft Seat), even after prolonged usage.

-

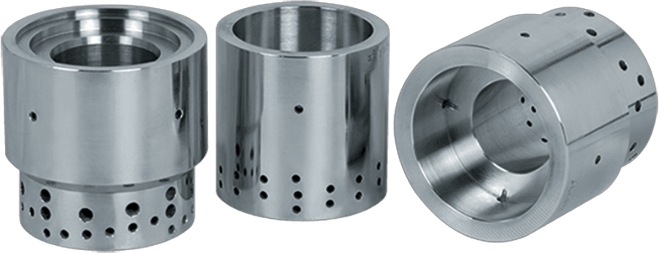

MegaFlo – Noise Attenuation Trim

• Reduces gaseous noise in control valves through advanced design.

• Utilizes a series of drilled hole cages to manage pressure drops.

• Maintains reasonable velocities and reduces turbulent energy.

• Generous plug-to-inner cage clearance prevents galling and seizing.

• Suitable for chemical plants, refineries, power plants, process industries, and nuclear industries.

CavFlo – Cavitation Control Trim