FITTINGS & MANIFOLDS

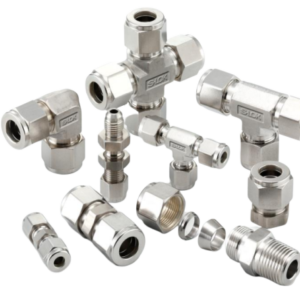

S-LOK TUBE FITTINGS

S-LOK TUBE FITTINGS

Tube Fittings have been designed specifically for the many demanding applications such as chemical, petroleum, power generating, pulp, paper and various types of manufacturing industries.

They provide a highly reliable, leak proof and torque free seal on all tubing connections. Tube Fittings are commonly used on

instrumentation, process and control systems, where high quality tube fittings are required

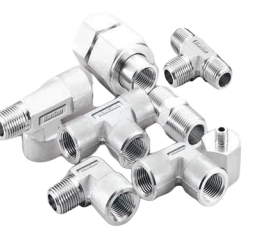

S-LOCK PIPE & WELD FITTINGS

-

All instrument thread fittings are designed in accordance with ASME

-

B31.3 for instrument and process.

-

Male thread are protected with cap.

-

Burr-free internal and outside surfaces.

-

NPT threads are based on requirement of ASME B1.20.1

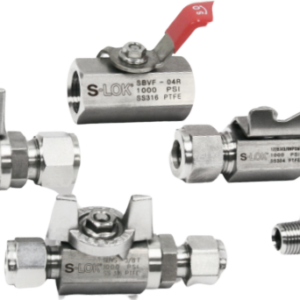

SBV10 SERIES BALL VALVE

•Compact design with hexagon bar-stock for high integrity.

•Working pressure up to 1000psig(69bar) at 100℉(38℃).

•Low torque quarter turn actuation.

•Size range of from 1/4″ to 1″tubing and piping.

•Various end connections : reliable S-LOK, NPT & ISO male & female.

•Butterfly handle is available as option.

SCV30 SERIES CHECK VALVE

•Pressure rating up to 3,000psig (206bar)@70!(21″).

•Temperrature rating up to 375!(191″) with Standard Vition O-ring.

•Choice of materials : Standard S316 and Brass.

•Cracking pressures include : 1/3, 1, 3, 10, 25, 50psi.

•Heat code traceability.

•Every valve is 100% factory tested for cracking and reseal.

SGV60 GAUGE & GAUGE ROOT VALVES

• Each instrument manifold is tested with nitrogen@1,000 psig (69 bar) to max. leak rate of 0.1 (SSCM).

• Hydrostatic shell test is performed at 1.5 times the working pressure as an option.

• Other tests are available upon request.

SRPV60 RISING PLUG VALVES

• Bi-directional flow control.

• Replaceable seat design: Acetal seat standard, optional PEEK and PFA are available.

• Non-rotating Stem Tip are composed for positive sealing and maximize soft seat life.

• Internal bonnet O-ring protects threads from external contamination.

• Isolated threads’ location above the sealing rings prevent media contamination and thread lubricant washout

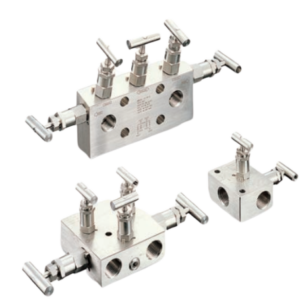

SMV, SMVD MANIFOLD