SEPARATOR VESSELS

Schultz Process Services (SPS)

VANE-TYPE SEPARATOR

Vane technology provides compact sizing, high efficiency and 100% turndown capabilities, as well as low pressure drop. Vane technology allows a wide range of configurations to meet application requirements.

-

316L EDP patented vane technology

-

3 Phase Applications

-

Combination of various SPS inlet devices

-

Inlet Multi-Swirlsep Centrifugal Devices

-

Conventional Tangential Inlet Devices

-

Inlet Pipe Diffuser

-

Dished Head Baffles ◾Vane Inlet Baffle

-

Slug Catchers

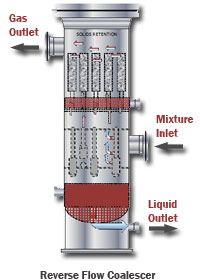

Reverse Flow Coalescers

Reverse flow coalescers (RFC) are used for applications requiring very high efficiency (0.3μ). In addition, the coalescer achieves the same performance removal of solid particles.

Design Features

RFC consist of a combination of two technologies:

1st Stage – Inlet chamber that employs one of the following features.

- KO – inlet baffle

- Vane mist extractor to reduce liquid loading to the elements

- Multi Cyclone for liquid and/or solid removal prior to the elements

2nd Stage – Outlet chamber

- High efficiency reverse flow coalescing elements

Filter Separators / Dry Gas Filters

The filter separation process involves the removal of solids, liquids or both from gas processing streams. Filter Separators are commonly used where high efficiency removal of both solids and liquids are required. Filter Separators consist of the combination of two technologies: filtration elements and vanes. Available in either horizontal or vertical vessel configuration.

Custom Features

- Full instrumentation/skid packages

- Quick opening closures for filter element removal

- Sumps or Lower Barrel configuration

Design Features

- Stainless steel constructed filter element carriers

- USA manufactured filters

- 316L EDP patented vanes

Single & Multi-Cyclones Centrifugal Separators